Is a SATA Interface Right for your Embedded OEM Application?

With SATA flash storage devices becoming the norm for SSDs in the client PC and enterprise market segment, many design engineers are considering these for their Embedded OEM systems. This article takes a look at several SATA solutions which are available and also some key points which should be taken into consideration when deciding which SATA device to use.

First, let’s take a look at the mainstream SATA SSD being used in the client and enterprise market segments.

The focus of this market is cost and performance and not reliability, BOM-control and/or long life cycles. Typical requirements are for a product that will last 2-3 years in a relatively benign temperature and shock and vibration environment. The duty cycle for a client PC in most instances is relatively light. For enterprise solutions, the SSD is used as a cache and expected to have a finite life cycle once the TBW (Tera Bytes Written) endurance is consumed.

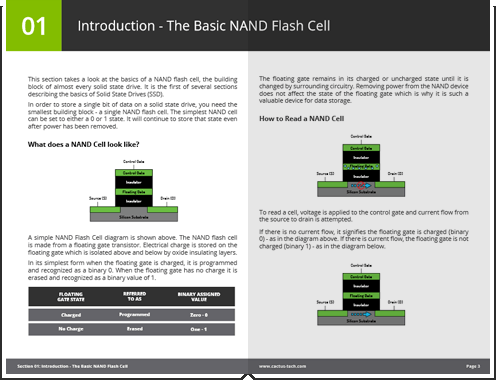

For this reason, the mainstream SATA SSD are built using lower cost NAND memory which also comes with much lower endurance cycles such as TLC (Tri Level Cell) NAND. A detailed SSD 101 EBook explains and illustrates the differences in NAND memory type and can be downloaded below.

Now consider an Embedded OEM application where there is a need to operate in the field for 5 to 10 or more years without service. In some cases, it is a harsh environment, in others it is just not practical or desired to visit the location of the system.

In these cases, a more reliable solution is needed. Hence the need for Industrial Grade SATA Devices for the most reliable, long life applications and Industrial MLC SATA Devices for a BOM-controlled, relatively long life solution in environments with lower endurance and less harsh duty cycles and environmental conditions.

A Number of SATA Form Factors to Choose:

The advantages of the SATA interface is its speed. Although at lower densities, the speed advantage may be lower than expected due to less channels for the controller to stripe across. With this speed advantage it is also more power hunger than other interface devices used in the Embedded World like IDE/ATA and SD interface.

2.5” SATA Solid State Drive:

As mentioned above there are several different “grades” of 2.5” SATA SSD available. Cactus technologies designs and manufactures the Industrial Grade 2.5” SATA SSD and Industrial MLC 2.5” SATA SSD varieties, but not the Consumer or Enterprise parts prevalent in the non-Embedded market today.

It is important to evaluate the requirements of your embedded design when making the decision on which type of SATA SSD.

CFast - A Modular, Packaged Solution for Embedded OEM Designs:

The CFast card is based on the popular legacy CompactFlash card. CFast is defined by the CompactFlash Association as a faster version of the IDE/ATA interface CompactFlash card. It is able to achieve this higher performance by using a SATA interface.

The CFast card is based on the popular legacy CompactFlash card. CFast is defined by the CompactFlash Association as a faster version of the IDE/ATA interface CompactFlash card. It is able to achieve this higher performance by using a SATA interface.

The modularity which made CompactFlash so popular in embedded environments holds true for the CFast as well. With capacities from 1GB to 256GB+ in a relatively small form factor, it makes an ideal solution for small rugged storage requirements. It is also a viable solution in applications where the end user will or may need to remove the storage from the system.

Cactus manufactures both Industrial CFast and Industrial MLC MLC CFast in different capacities and operating temperature ranges.

mSATA, Slim SATA and M.2:

For embedded OEM applications with a need for a non-removable solution with long life cycles, high reliability and locked-BOM control, Cactus offers several solutions.

For embedded OEM applications with a need for a non-removable solution with long life cycles, high reliability and locked-BOM control, Cactus offers several solutions.

By far, mSATA has emerged as the most popular of the embedded, mountable modules. Cactus offers an Industrial mSATA based on SLC NAND flash in capacities from as low as 1GB up to 64GB. Extended temperature ranges and extremely high endurance and resistance to corruption during unexpected power loss are what this part has become known for. A Industrial MLC version is also available.

Slim SATA is a much less popular form factor. Its advantage is the use of a standard SATA connector, the same as the 2.5” SATA SSD or hard drives. But it has never gained wide support in the market. For this reason, we suggest considering mSATA if you are planning to go the module route.

Finally, M.2 is a standard being driven by consumer electronics which is being considered by some embedded OEMs. It’s a small form factor, but its physical size can be one of several different versions. If you have a long life design and the market moves away from the physical dimensions of your selection, you may find yourself in for a large last time buy (if available) or a costly redesign of an old product you don’t want to devote additional resources to.

I hope you’ve found some of this information valuable. As always if you have any questions about your embedded or industrial OEM design, please reach out and contact us for assistance.