SLC NAND Flash is NOT all Created Equal

![]() For a long time, Industrial Grade flash storage products were considered anything made with SLC NAND. But as the generations of newer geometry SLC NAND arrive in the market, there are significant differences in reliability.

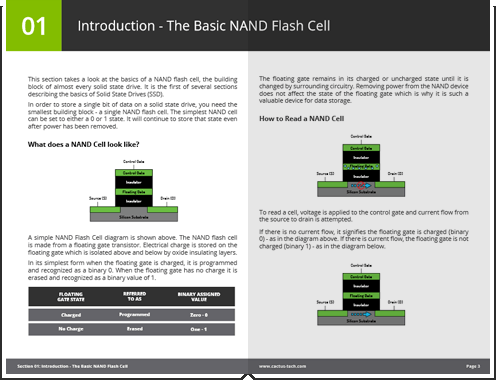

For a long time, Industrial Grade flash storage products were considered anything made with SLC NAND. But as the generations of newer geometry SLC NAND arrive in the market, there are significant differences in reliability.

Cactus Technologies focuses our efforts on the 43nm and 32nm SLC NAND. The larger the trace width, the more area there is for the NAND cells, which means a larger oxide layer which is needed to maintain a specific charge (data) in the cell. As cells are erased over time, this oxide layer is degraded and eventually will no longer hold a charge. The larger the cell/oxide layer the better.

For a detailed understanding of how a NAND cell works - download the SSD 101 EBook below.

Truly Industrial Grade products designed for the highest reliability are designed with the oldest, widest trace width SLC NAND geometry. We are planning to produce a more detailed technical marketing paper covering this subject in the next few months.

What's an OEM Designer to Do?

At this point it makes sense for any OEM designing an Embedded Industrial application to really understand the trace width of SLC NAND they are qualifying in their system. In addition to the controller, firmware and company supplying these parts, it is a key indicator of reliability.

If you would like to discuss this further, please contact us for more information.