SLC, pSLC, MLC and TLC Differences - Does Your Flash Storage SSD Make the Grade?

Not all SSD are created equal. There are enormous differences in ability to work at temperature, in poor power environments, under high duty cycles. When talking enormous, an Industrial Grade SSD can have as much as 300 times (yes, 300 times, not 300%) more write endurance cycles per physical block of data.

An OEM designer should carefully choose which “Grade” of flash storage is right for their application if they want a system that will operate over the field life of their product.

The most common mistake some engineers make is believing all SSD are equally reliable, and therefore, only focus on cost, performance and high capacity. A lower endurance, high performance SSD may work great in the lab if an accelerated life test to judge longevity is not performed. But, once in the field, the true identity of the SSD is revealed and failures begin to occur - increasing as more endurance cycles, longer time at temperature, significant reads/writes and other forces take effect.

How to Choose the Right Grade?

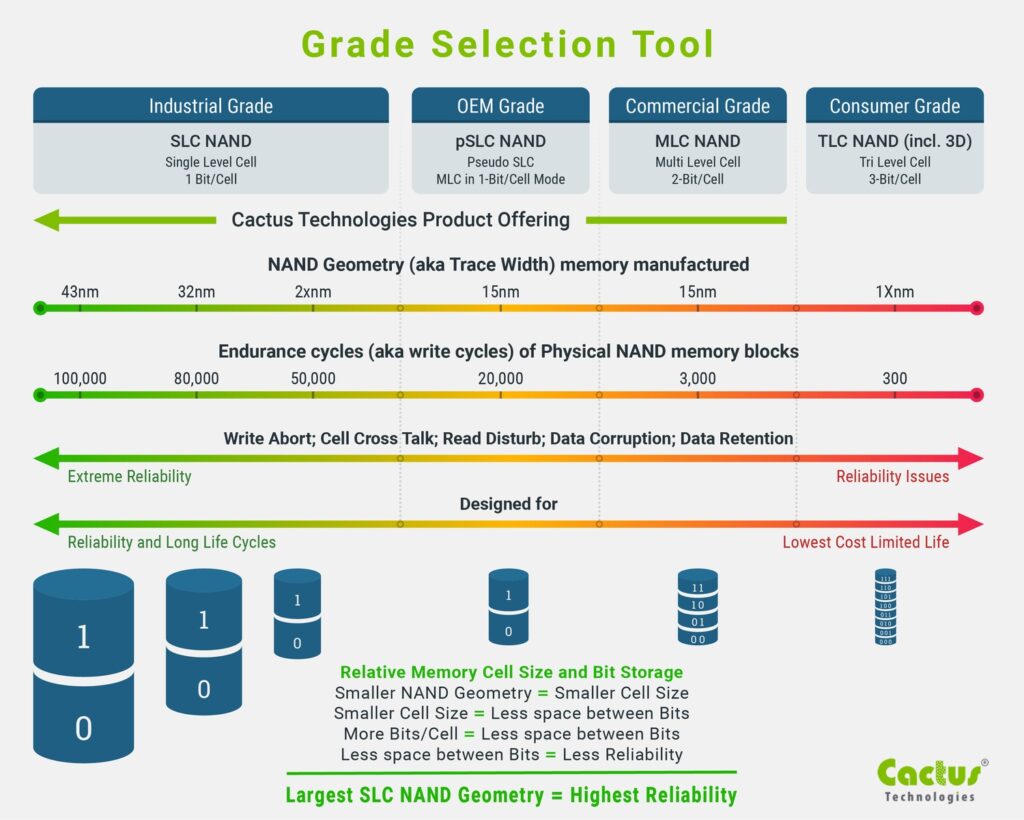

There are several key attributes of SSD which determine their “Grade.”NAND TypeThe first and most important is the type of NAND flash being used. There are a few varieties to choose from which vary widely in reliability which affects cost.The chart at the top of this article shows SLC, pSLC, MLC and TLC NAND and the associated trace width manufacturing, raw block write cycles and where they fit on the spectrum of overall reliability, life cycles and cost. At the bottom of the chart the relative sizes and number of bits being stored in the different NAND cells.As stated on the chart, the largest SLC NAND cell size equals the most reliability. With only one bit per cell to be concerned with and a large cell to store this single bit, there is no wonder why this is the case.As in the MLC and TLC NAND, more bits per cell stored in a smaller physical cell leave less guard band between the cells. This lower guard band makes the cell more susceptible to temperature extremes, write abort conditions, flipped bits, data corruption, cell cross talk and other factors.

There are several key attributes of SSD which determine their “Grade.”NAND TypeThe first and most important is the type of NAND flash being used. There are a few varieties to choose from which vary widely in reliability which affects cost.The chart at the top of this article shows SLC, pSLC, MLC and TLC NAND and the associated trace width manufacturing, raw block write cycles and where they fit on the spectrum of overall reliability, life cycles and cost. At the bottom of the chart the relative sizes and number of bits being stored in the different NAND cells.As stated on the chart, the largest SLC NAND cell size equals the most reliability. With only one bit per cell to be concerned with and a large cell to store this single bit, there is no wonder why this is the case.As in the MLC and TLC NAND, more bits per cell stored in a smaller physical cell leave less guard band between the cells. This lower guard band makes the cell more susceptible to temperature extremes, write abort conditions, flipped bits, data corruption, cell cross talk and other factors.

NAND Geometry (Trace Width) Manufacturing

As touched on above, the Trace Width used to manufacture the NAND memory increases the number of cells per area of silicon. The smaller the Trace Width, the less space between cells. The larger the Trace Width, the more space between cells.

SLC NAND still is available and will be for at least several more years in the 43nm, 32nm and 24/20nm sizes. Even though all are SLC cell types, there is a huge reliability advantage in the 43nm & 32nm over the 24nm & 20nm SLC. If reliability is what you seek, stay with 43nm & 32nm SLC NAND based SSD.

Industrial Grade - What is it?

Industrial MLC - What is it?

So why do people use MLC NAND? Because it’s much less expensive than SLC NAND and may be acceptable if their application does not need the higher reliability and longer life cycles of Industrial Grade.

Cactus offers Industrial MLC products, but is one of the few companies which locks the BOM (Bill-Of-Material) so what you initially qualify is what you receive for your ongoing production orders.

Industrial pSLC - What is it?

Industrial pSLC offers better pricing than Industrial Grade, but still has to contend with similar unexpected power loss, cell cross talk, read disturb, data corruption and data retention issues of MLC.

Cactus offers Industrial pSLC products, but is one of the few companies which locks the BOM (Bill-Of-Material) so what you initially qualify is what you receive for your ongoing production orders.

Consumer Grade - What is it?

Consumer Grade products are built for lowest cost and in some cases highest performance. They use the lowest cost NAND flash which today is TLC NAND. TLC stands for Tri Level Cell and signifies storing voltage at 8 different levels in the cell to represent 3-bits (000, 001, 010, 011, 100, 101, 110, 111).

Built on the same small manufacturing geometries as MLC NAND, TLC has even more issues with unexpected power loss, cell cross talk, read disturb, data corruption and data retention as well as difficulties at wide temperature ranges.

Consumer flash storage products are not typically satisfactory for OEM and Industrial applications and do not come with a consistent Bill-Of-Material.

In Conclusion….

A designer of an OEM system or system integrator using a motherboard or single board computer that needs to decide on a flash storage solution, should consider their options carefully.

There are significant differences between product offerings which are not evident at first glance or on the latest glossy brochure.

Industrial Grade offers the most reliable solution and OEM/Industrial MLC offer lower cost solutions which trade reliability for better cost. Consumer Grade products should be viewed critically for anything other than low duty cycle applications.

If you need assistance with an OEM design or needing special features, please contact us.