MLC NAND Considerations in Wide Temperature Range Industrial Embedded Applications

Due to the cost advantages of MLC NAND based flash storage versus Industrial Grade SLC devices, many MLC parts are finding their way into wide temperature applications. An OEM making this decision should thoroughly consider several items before using MLC over time at extended temp.At 8GB and less, an Industrial SLC NAND based device can be justified within an OEM designer’s storage budget - when longer life, high endurance and wide temperature advantages are taken into consideration. As detailed in this Total Cost of Ownership article, a solid analysis will provide the needed validation.

Due to the cost advantages of MLC NAND based flash storage versus Industrial Grade SLC devices, many MLC parts are finding their way into wide temperature applications. An OEM making this decision should thoroughly consider several items before using MLC over time at extended temp.At 8GB and less, an Industrial SLC NAND based device can be justified within an OEM designer’s storage budget - when longer life, high endurance and wide temperature advantages are taken into consideration. As detailed in this Total Cost of Ownership article, a solid analysis will provide the needed validation.

When higher capacity requirements of 16GB and beyond are needed for an extended temperature industrial-embedded application, system designers have the dilemma to choose between two options.

Option 1 - SLC NAND: Extremely reliable Industrial SSD which can endure severe temperature environments in the -45C to 90C range for well over a decade in most industrial-embedded applications.

Option 2 - MLC NAND: Much lower cost SSD using NAND targeted for lower endurance applications in the 0C to 70C operating range.

Why the temperature difference between MLC and SLC NAND?

There are two reasons for the cost and temperature differences between MLC and SLC NAND based SSD.

There are two reasons for the cost and temperature differences between MLC and SLC NAND based SSD.

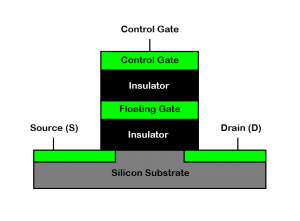

First, there are two bits per cell on MLC NAND, making the need for much more precise programming and retrieval of the exact voltage (binary state) of each cell. With SLC NAND, there is only one bit per cell, so the circuitry is much more forgiving as temperature extremes effect its operation.

Second, the MLC NAND die are built with cost as a priority. To achieve this, manufacturing geometries must constantly shrink to finer and finer trace widths. Insulation from small oxide layers keep the storage section of the NAND cell from losing its charge. The thicker the oxide layers - the better the data retention.

Unfortunately, with finer trace widths, this oxide layer shrinks as well. As an example, MLC NAND is moving rapidly to 15nm technology today, while Cactus will continue to produce many of our Industrial Grade Flash Storage Devices with highly reliable 43nm SLC NAND for years to come.

In conclusion, a designer of industrial-embedded systems should perform a solid due diligence when considering MLC NAND for wide temperature environments. The full life of the OEM system should be taken into consideration, not just a short qualification period.

This has been a brief overview of MLC and SLC SSD in wide temperature environments. In addition to Industrial Grade Flash Storage Products, Cactus also offers MLC NAND devices with firm BOM control for applications not requiring Industrial Grade.

If you would like to discuss your specific system needs, please contact a Cactus Expert.